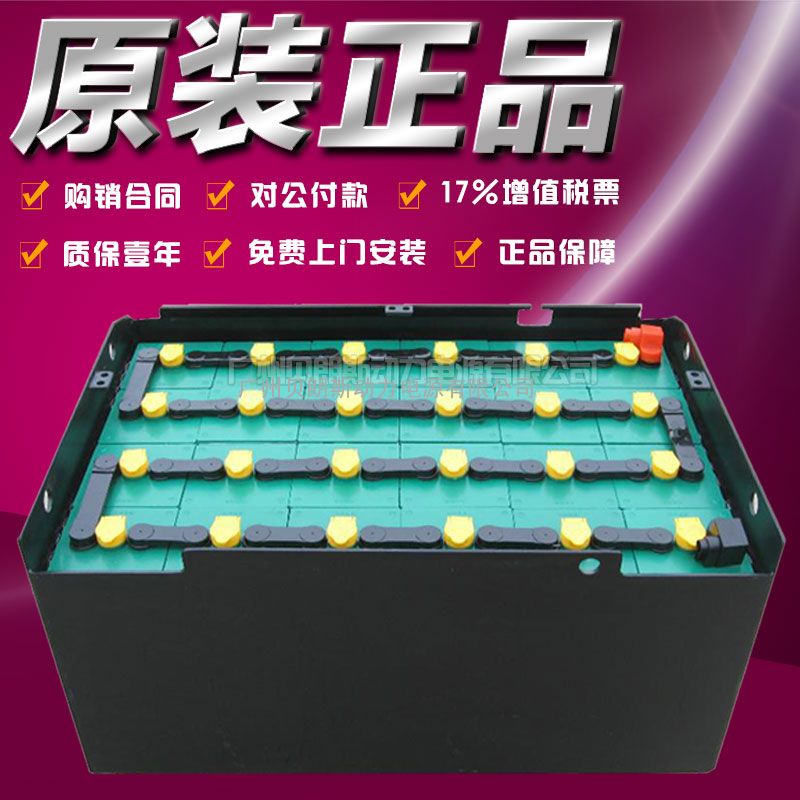

TCMC叉车蓄电池品牌大全概括了贝朗斯、日本GS、KOBE、日立等进口叉车电瓶,日本TCMC叉车主要由TCM叉车制造,广泛应用冷库、食品工业、仓储等场所,TCMC叉车电瓶价格根据铁箱尺寸、电压、容量、叉车电池品牌决定,广州贝朗斯公司配套出的叉车蓄电池组寿命基本4年以上,动力强劲,电解液挥发少,在各个领域得到应用。

叉车蓄电池依靠2V的单体串联组成,混合更加强的电流,以达到驱动叉车行驶为目的,单体在***初期,采用管式 极板组合,初充电争两个阶段进行:首先用初充电电流充到电解液放出气泡,单格电压升到2.3~2.4V为止。然后将电流降为1/2初充电电流,继续充到电 解液放出剧烈的气泡,比征和电压连续3h稳定不变为止。全部充电时间约为45~65h,充电过程中应常测量电解液温度用电流减半、停止充电或冷却的方法, 将温度控制在35~40℃,初充电完毕时,若电解液比重不合规定,应用蒸馏水或比重为1.4的电解液进行调整。调整后再充电2h,直至比重符合规定时为 止,叉车蓄电池不能过度放电,包括柴油和电叉都一样,过度充电或者放电都对电池本身寿命影响,新蓄电池*次充电后往往达不到容量,应进行放电循环。用 20hh时放电率放电(即用额定容量1/20的电流放电至单格电压降到1.75V为止),然后再补充充电电流充足,经过一次充、放电循环若容量仍低于额定 容量的90%时,应再进行一次充、放电循环,叉车电池单体日后在使用存在不均衡的状态,要密切检查,不然电池续航能力下降很快的。

TCMC叉车电瓶哪家好?选择广州贝朗斯,给您好的服务,优惠的价格,技术参数齐全,库存充足, 叉车电池的品质如何鉴 别,这个问题关系到叉车使用企业的用车成本,购买一组质量稳定的叉车电池可以省下后期大量的麻烦事,我们见过的案例,曾经佛山地区有一个客户从镇江某电池 厂购买了一组48V550AH的合力叉车用电池,使用半年后单体出现冒烟、电解液挥发过快,使用时间缩短等情况,以前每两周补加蒸馏水一次,现在每天要加 一次,而且充电是时候必须人工值守,及时补水,不然马上烧干,而且产生大量气体及难闻的异味,整个充电机房人在里面待上10分钟承受不了,空气里充斥大量 刺鼻、刺眼的酸雾,针对这种情况,客户将信息反馈到叉车电池生产厂家,工厂居然说加水加得快很正常,拒绝更换新的单体电池,而且对于技术上的问题咨询显得 很不耐烦,无奈,***终客户找到了我们,我们派出工程师到现场,排查了车辆电流、叉车充电系统的问题,检查到其中连接的有四个叉车电池单体出现了微短路的情 况,电解液比重密度为零,每个单体电池零点几伏,整台叉车使用时间不到2小时,频繁的充电,导致其余二十个单体电池密度不均匀。

TCMC叉车蓄电池质量怎么样?其实使用质量与维护保养很关键, 电瓶是叉车的动力源,性能的好坏将直接影响电瓶叉车的使用,在日常使用过程中,应严格按规范做好蓄电池的日常检查与维护工作,并按蓄电池维护规定执行。这种牵引叉车蓄电池主要分为英标BS158宽系列,德标DIN198宽系列,采用管式的极板研究制造,初期实行三充三放,使电瓶组实行完全百分百化学反应,广泛应用于国产进口系列电动叉车。

TCMC forklift battery brand Daquan summarizes Berans, Japan GS, KOBE, Hitachi and other imported forklift battery, Japan TCMC forklift mainly manufactured by TCM forklift, widely used in cold storage, food industry, warehousing and other places, TCMC forklift battery price according to the iron box size, voltage, capacity, forklift battery brand, forklift battery life in Guangzhou bay the basic lens company supporting more than 4 years, strong power, electrolyte less volatile,

has been applied in various fields. Series forklift battery monomer composition on 2V, current hybrid more, in order to drive forklift driving for the purpose of monomer in the initial stage, the tubular plate combination, for initial charge in two stages: first using the initial charge current charge to electrolyte release bubbles, single cell voltage up to 2.3~2.4V. Then, the current is reduced to 1/2, the initial charge current continues to charge the electrolyte, and the bubbles are released. The constant voltage and the continuous 3H are stable. All the charging time is about 45~65h, often with the current half, electrolyte temperature measurement method of charging or cooling stop charging process, the temperature controlled at 35~40 DEG C, initial charging is completed, if the electrolyte density irregularities, using distilled water or electrolyte in the proportion of 1.4 adjustment. After adjusting the charge 2h, until the proportion in conformity with the provisions of the time, forklift battery cannot excessive discharge, including diesel and electric fork, excessive charging or discharging effect on battery life, new battery after the first charge is often less than the capacity, should discharge cycle. With the discharge rate of 20hh (i.e. with discharge current to single voltage rated capacity of 1/20 to 1.75V so far), and then add the charging current is sufficient, after a charge and discharge cycle if the capacity is still lower than the rated capacity of 90%, should be a charge and discharge cycle, forklift battery monomer day there exists imbalance in use, to close inspection, or battery capacity decreased quickly.

TCMC forklift battery which is good? Guangzhou Bei longs, give you good service, preferential price, complete technical parameters, adequate inventory, how to identify the quality of forklift battery, this issue is related to the use of forklift enterprise cost of car, buy a set of forklift battery with stable quality can save a lot of trouble later, we have seen the case, once in Foshan area have forklift a customer purchases a group of 48V550AH from a Zhenjiang battery factory battery, half a year after the use of monomer smoke and volatile electrolyte appear too fast, the use of time, every two weeks before adding distilled water once a day, now, and the charge is must Manual duty otherwise, the timely replenishment, immediately dry, odor and produce large amounts of gas and foul, the real people in the charger and stay there for 10 minutes to bear, in the air. With lots of mist pungent, dazzling, in view of this situation, the customer will forklift battery manufacturer information feedback, the factory actually said the water too quickly is normal, refused to replace the new battery, but also for the technical problems of consultation is very impatient, helpless, the final customer found us, we sent to the engineer the scene investigation vehicle current, forklift charging system, which is connected to the check four forklift battery monomer appeared micro short circuit situation, the proportion of electrolyte density is zero, each single battery a few tenths of a volt, a forklift use time less than 2 hours, frequent charging, lead to the rest of the twenty single cell density.

How TCMC forklift battery quality? Actually use quality and maintenance is the key, the battery is the power source of the forklift, performance will directly affect the use of battery forklift, in daily use, should be strictly according to the standard daily check the battery and maintenance work, and implement according to the provisions of battery maintenance. The traction forklift battery is mainly divided into the British standard BS158 wide series, German standard DIN198 wide plate series, the research on the tube type of manufacturing, the early phase of the three charge three, so the battery group to implement fully 100% chemical reaction, is widely used in domestic and imported electric forklift series.